Scale Up Challenge? Read On

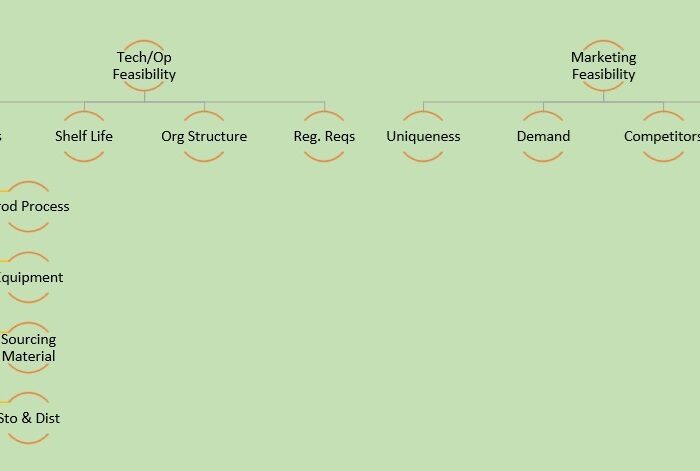

The scale up process is a part of the product development process. When the prototype is approved for a benchtop sample, then the real work starts, also known as the scale up. Making 1-2 pound samples is much different then producing thousands of pounds of samples. We need the whole procedure to scale up the product from the benchtop to the real production floor. Once a satisfactory product is obtained, the next step is to scale-up the prototype/recipe for mass production, packaging, distribution, and sales. There could be bottlenecks like ingredients behaving differently, flavors changing, and equipment issues arising. To make the scale up process easy, we need to evaluate the following steps.

The Process:

Formula Scale Up

The scaled-up formula of the product may be very different from the benchtop formula because of differences in taste, texture, aroma, or appearance. It may be possible to modify the scaled-up formulation so that it more closely resembles the benchtop formula. Therefore, the scale-up process may require multiple trials.

There are three main parameters we need to keep in mind while doing scale up: functionality, cost, and availability. We can find alternative raw materials which are close to the raw material used in the benchtop sample. This way we have multiple vendors for particular raw materials which can save cost and fulfill the demands. Developing a batch sheet based on the benchtop formula and procedure is always helpful to the person who is helping on the production floor during scaling up.

Process and Equipment Scale Up

The first step in the process and equipment scale-up is to define the product and package used to pack the product.

Heat transfer (cooking/Pasteurization and cooling) and mixing in tanks or vessels are two of the most common treatments in food processing. Both of these treatments are heavily dependent on the unit surface area to volume relationship. Scale up process may take longer to complete the cooking and cooling process. We need to adjust the process on a batch sheet based on the first trial. Movement of the product from step to step in processing may become more complex on a scale-up.

Thoughtful positioning of tanks and process equipment can minimize product transfer requirements. When possible, elevated equipment may be used to gravity-feed the product to the next step.

We need to arrange equipment so that there will be minimal wastage.

Benchtop samples may be packed by hand, so we need to make sure the finished products are being packed properly in order to maintain its freshness and quality parameter during the shelf life.

Facility Scale Up

For facility scale up we need to find out if any additional equipment or additional parts need to be added to the current equipment to achieve the product close to the benchtop sample in terms of texture, color and flavor.

We need to make sure how that equipment will be sanitized before and after production. We also need to consider any special personnel needed to operate the equipment.

If we are running any allergens through the equipment (Food Allergens), then we need to use appropriate sanitation methods and chemicals, which are going to be used to clean the proteins of the particular allergen.

Certifications and regulatory compliances are required to be confirmed and verified during the scale-up process. This is an essential part of this process.

My Two Cents

The food product scale-up process is thrilling and challenging, which requires a properly organized, flexible, and consistent approach for success. Always celebrate success when the formula and its process for commercial production has been determined to achieve the desired product!

!! Patience is key. Don’t lose it during the scale up process!!