Kick off food product development in Co-Manufacturing

In most co-manufacturing facilities, the ideation phase is to understand the customer’s needs and requirements, and developing a product based on that.

Usually there are two criteria of product development in Co-Manufecturing, the first criteria being that one has to match the product with the existing product in the market by developing their own recipe with improvements. The second criteria is about the development process which mimics the customer’s recipe by using the Co-Manufacturer’s facility and equipment.

Lets dig in the initial stage of product development based on both criteria.

First if you are developing a product, match the existing market product with a product from another competitor.

You need to buy as many products from different competitors which are close to the requested product by your customer. Evaluate these market samples using physical, chemical, and microbiological testing. Understand the best attributes amongst all the samples that you can use in the PD process. Pick one market sample that has the best match to the product you need to develop and consider that sample as a control sample. Study the gap in the control samples that you can fill during your product development process.

Next, read the ingredients deck, nutritional values, and other information regarding claims or allergens carefully.

After having an idea of the basic attributes of your control sample, develop a target specification sheet for your final product based on sensory attributes (color, taste, texture, flavor etc.) and chemical attributes (PH, TA, TS, Viscosity). This will be beneficial to your PD process.

Once you have the specification sheet, reach out to your supply chain team regarding any raw materials. Discuss the inventory you have in house and what extra raw materials you need.

You can reach out to your vendor about specific ingredients if you need to discuss the functionality of the raw material. Always be open to talk to your vendor R & D team for technical support.

After working on the raw material sourcing, start developing the prototype for the benchtop samples.

Develop the process flow instructions to make benchtop samples

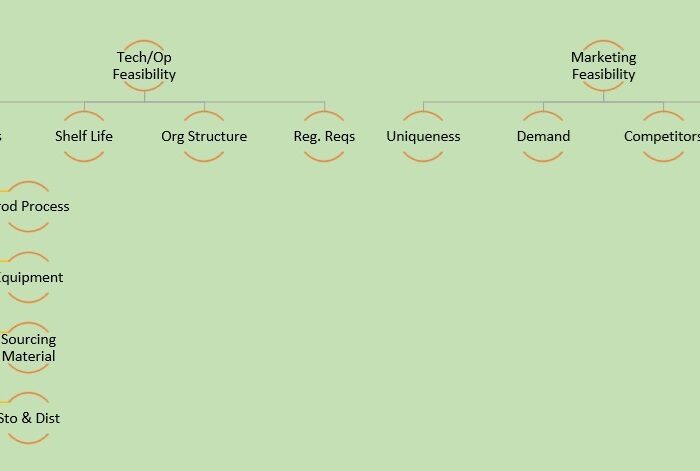

Study your process very closely to understand the feasibility of the benchtop sample scale up.

Second, if you have a formulation given by the customer and you need to use that formulation to develop the product on benchtop, replicate the process at your manufacturing facility.

You can always track the process with a kick off meeting. This meeting is vital to start the development process and to understand the customer’s needs before you initiate the PD process. After having clarity on the product, ask your customer for the vendor they are using for the raw material, making sure to get the exact item number for the raw materials. Sometimes, the vendor supply customizes blends to particular brand owners, so doing this will ensure you can develop the product on time.

After getting all raw materials and the vendor list, reach out to the vendors for samples of the raw materials to try on your benchtop samples. Make sure to compare them against the existing product in the market.

Conclusion

The journey of product development has just begun. Perform the product development process with dedication so that you can achive your goals in a timely manner and have it turn out the way you wanted.

Reference links

Sensory Evaluation Methods for Food and Beverage Products